General Description

- Pick-up Coils

- Generator Filters

- Broken Wires or Connections

Troubleshooting

Make sure the tone wheel is spinning.

This may sound simple but tone wheels can stop due to lack of oiling or really bad worn out bearings or a pick-up magnet pushed into the wheel.

First determine the location of the tone wheel that you suspect. You can do this by the known frequency and the generator charts.

Another way to determine the particular wheel is to take a clip lead jumper wire and connect one end to the back of a drawbar. Make sure the drawbar is turned on with the preset and pulled out about halfway. Take the other end of the test clip lead and connect it one at a time to each terminal on the generator to test for a tone. This is a very easy and accurate way to test every tone generated by the tone generator. You can adjust the drawbar for a comfortable listening level.

When you locate the bad or missing tone, follow the wire from that terminal to the filter. You will see another wire on the opposite side of the filter which goes to the tone wheel pick-up. Clip your wire there to verify that a signal is coming from the pick-up.

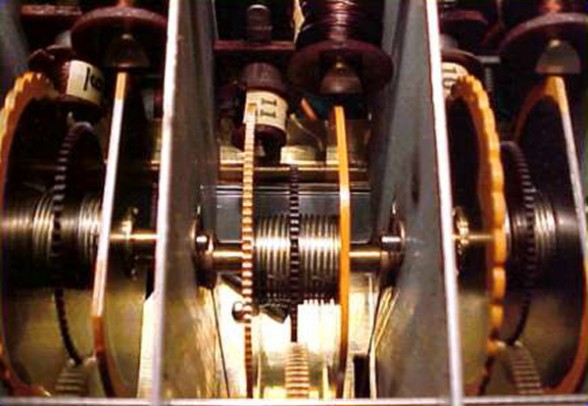

Now if you have no signal still, you must see if the wheel for that tone is spinning. The wheels on the back side of the generator are easier to get to than the front. You can lift the manuals, (four large bolts and a couple of screws) and then see the front of the generator. If the wheels (two per bin) are not spinning, you can give them a spin by hand and they may start to spin.

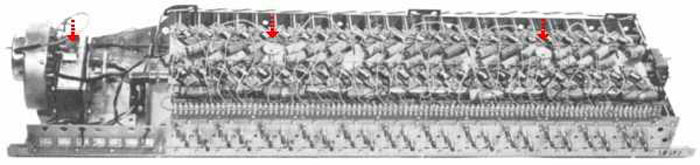

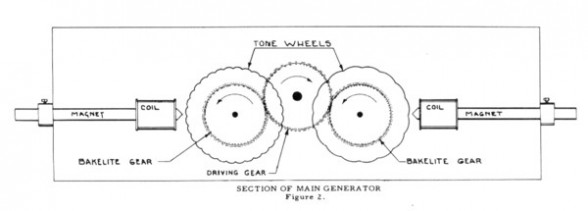

Looking at the above picture you will see that the two tone wheels in the center are located on each side of the bakelite gear which is driven by the brass gear on the main shaft.

The tone wheels are connected to the bakelite gear only by the springs located in between the tone wheels and the bakelite gear. If the tone wheel shaft is stuck, the clutch action of the springs allows the bakelite gear to still spin thus not causing the entire generator to stop. Interestingly if enough tone wheels are stuck they can put enough drag on the generator to keep it from running.

However, running the generator with stuck wheels causes wear to the drive gear on the stuck wheels. If allowed to run long enough it can damage this drive gear causing the tones to flutter or not sound steady in pitch. This problem is mostly not repairable so best to avoid it. Make sure all wheels are turning or fix the problem.

The good news is that after a little oiling and manual spinning you will almost always get the wheels to spin.

The bad news is that if you have a wheel that will not spin due to a real worn out bearing, or a broken bakelite gear or any mechanical problem which does not allow the wheels to spin, there is in reality no repair here. These wheels are sandwiched into the generator as it is put together. Also, there are no parts you can order. If you wanted to disassemble a generator and had say another generator to get parts from, it would be simpler to swap generators.

Another possibility is a Trek II Product that replaces a dead note electronically.